MYTILINEOS Holdings Sustainability Report

2014

MYTILINEOS Holdings Sustainability Report

2014

54

55

The exact number of accidents was four (4), all of which involved male

employees. Three accidents occurred in the Metallurgy & Mining Sector

(at the Electrolysis and Anodes Departments of ALUMINIUM OF GREECE)

and one in the EPC Projects Sector (at a METKA S.A. construction site in

Jordan). Each of these accidents caused an interruption of work, due to

injuries sustained by employees in their limbs and one lumbar contu-

sion suffered by one employee. The main causes of these accidents were

related to the employees' failure to identify the risks involved and to the

breach of the safety rules and guidelines established in the MYTILINEOS

Group subsidiaries.

All incidents were analysed using the "Root Cause Analysis” method

and investigated thoroughly, the results were understood and relevant

corrective actions were planned (including, for each action, a person in

charge, a deadline and a completion date), with the aim of informing em-

ployees and preventing any conditions which could cause such accidents

to happen again from arising. More specifically:

METKA S.A. (Construction Site):

• Unnecessary materials were systematically removed from work

areas.

• Special training in work instructions was carried out for employ-

ees.

ALUMINIUM OF GREECE (Electrolysis Department):

• An action plan was developed, focusing on raising the awareness

of the Management hierarchy and of personnel.

• An action plan for repairing anomalies on the Department's floor

was developed, in collaboration with the Production Support De-

partment.

• Management Safety Visits (MSVs) to the Electrolysis and Cast

House Departments were stepped up and the Safe Professional

Move (SPM) instructions were revised.

• The number of "Risk Identification" forms completed by Shift Fore-

men was increased.

• Daily meetings of the Functional Organisational Units (FOUs) were

held to discuss safety issues.

• All work methods were revised, placing emphasis on any unclear

points.

ALUMINIUM OF GREECE (Anodes Department):

• The technical solutions related to the accident were implemented.

• The dangerous points/interventions in the Anodes transporters

were recorded by the Anodes Furnace Functional Organisational

Unit (FOU).

• Management Safety Visits (MSVs) were made outside the morning

working hours.

• The adherence to the Safety Instructions by the employees was

inspected.

• “Zero tolerance walks” were established by the Department's Chief

Foreman.

• Interviews/visits to the work posts by the Supervisor and the Chief

Foreman of the Department were made.

In the Metallurgy & Mining sector, the Group evaluates its performance

against the performance of similar plants and intensifies its efforts for

continuous improvement. The investigation of accidents shows the

need for a comprehensive assessment of the risks present at the work-

place, in tandem with the need for constant alertness in order to pre-

vent accidents. In this respect, ALUMINIUM OF GREECE already applies

procedures for recording and investigating potential serious accidents

and the necessary corrective measures are taken. In the Sustainability

Report 2015, the Safety indicators will be expanded to also include refer-

ences to potentially serious accidents recorded across the entire range

of the Plant’s operations, together with relevant qualitative data.

Health is an equally important part of our sustainable and responsible

growth in the Metallurgy & Mining Sector and one in which the Group

has been consistently investing through ALUMINIUM OF GREECE since

its establishment. In 2014, the Company succeeded in reporting, for the

fourth consecutive year, nil incidents related to occupational diseases

This is due to the implementation of the

Occupational Risk Assess-

ment (ORA)

procedure, which refers to all factors in the work environ-

ment which can affect the health of employees and aims to constantly

improve work conditions. The ORA is a quantitative tool that relies on

measurements of harmful factors, which as a rule are carried out us-

ing personal samplers and, in general, measurement instruments that

employees carry on their person during the working day. After math-

ematical processing, these measurements are compared to the expo-

sure limit values determined by the laws in force. The processing of

this data offers the possibility of establishing a complete record of the

exposure of employees and of developing a comprehensive action plan

in order to maintain the target of “ZERO OCCUPATIONAL DISEASES AT

WORK”. Today, a total of eight (8) harmful factors are monitored sys-

tematically, including noise, dust, fluorine compounds, sulphur dioxide,

carbon monoxide, polycyclic aromatic hydrocarbons, thermal shock

and beryllium.

Managing the safety of the personnel of independent contractors is a par-

ticular challenge for the Group’s subsidiaries, which can be successfully

met mainly through initiatives aimed at changing the current attitude to-

wards accident prevention. This Report presents in a separate section, for

the first time, the Health & Safety indicators for the personnel of contractors

working for the Group in various activities. According to these indicators,

11 accidents with interruption of work occurred in 2014, of which five in the

Metallurgy and Mining Sector and six in EPC Projects Sector.

In the Metallurgy & Mining Sector, the accidents occurred in three

different contractor businesses working within the premises of the

ALUMINIUM OF GREECE plant and involved fractured limbs, with one

of them involving the partial amputation of a distal phalanx. These in-

juries were caused primarily by improper handling of equipment and

tools. The corrective actions taken involved technical improvements in

the equipment and the adoption of measures to improve ergonomics

for employees and were also accompanied by revisions and additions

to work methods.

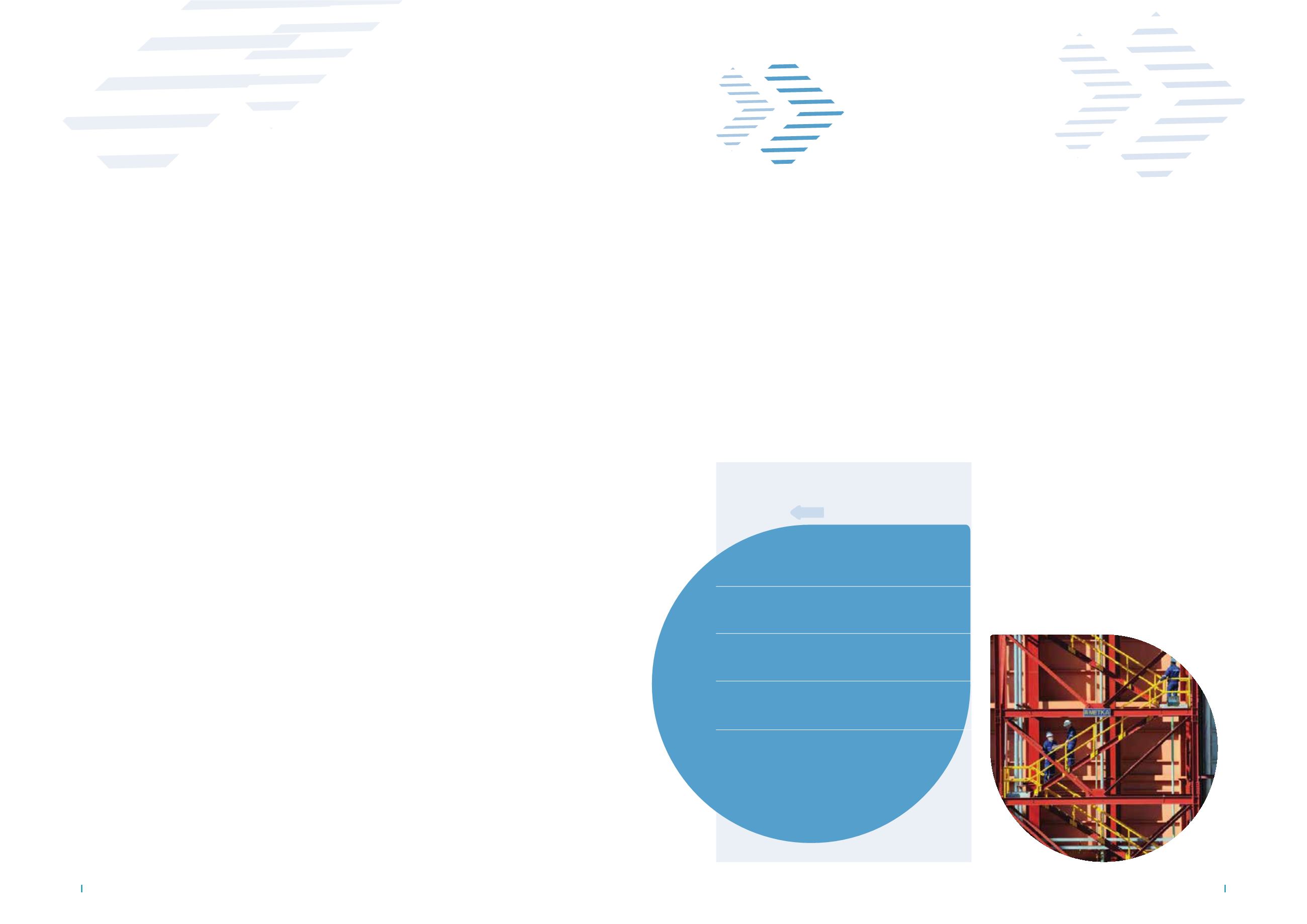

Health & Safety Indicators

Personnel of the Group’s independent

contractors

2014

Injury Rate (IR)

IR (Total)

0.46

IR (Men)

0.45

IR (Women)

0.00

Occupational Diseases Rate (ODR)

ODR (Total)

0.00

ODR (Men)

0.00

ODR (Women)

0.00

Lost Days Rate (LDR)

LDR (Total)

7.76

LDR (Men)

7.85

LDR (Women)

0.00

Absenteeism Rate (AR)

AR (Total)

0.00%

AR (Men)

0.00%

AR (Women)

0.00%

Safety of the personnel of independent contractors

In addition to the actions carried out after the accidents, a number of

specific initiatives for raising personnel awareness also contributed to

accident prevention. These initiatives were carried out in collaboration

with members of the PHSC (Plant Health and Safety Committee) and

involved the following:

• Placing posters at the plant's entry gate and at selected locations

inside it, on subjects such as the use of seatbelts, the use of per-

sonal protection equipment, driving and using mobile phones.

• Placing posters at the plant bus stops, designed to raise personnel

awareness of safety issues and featuring actual plant employees

as models in the poster photographs.

• Placing a mannequin in the canteen area, dressed up as an em-

ployee with the personal protection equipment which is mandato-

ry within the plant area and holding a written safety message.

In the EPC Projects sector, the accidents occurred in the construction

sites of METKA S.A. and were caused by a falling object, employees

falling into an excavation pit and obstacles on the same level. All the

accidents involved male employees and each one of them resulted in

an interruption of work for three or more days. The immediate actions

taken after the accidents involved the provision of medical care, consist-

ing in the administration of first aid at the project site and the transport

of the injured employee to an associated hospital for further treatment.

All the employees involved in the accidents have now returned to work

and the corrective actions taken were the following:

• The excavation pits were fenced off and appropriate signs were

put up.

• Unusable/waste materials were removed from the work areas.

• The employees of contractors were provided with training in work

instructions.

(G4-LA6)