24

25

MYTILINEOS HOLDINGS - SUSTAINABILITY REPORT

2016

Group policy on adapting to climate change:

-

adapting-to-climatechange

7.1 Climate Change

MYTILINEOS Group constantly aims to carry out its business activity

in line with the principles of sustainable growth and, therefore,

aims to minimise its contribution to climate change. The Group

has adopted certain practices to deal with climate change, the most

importantonesbeingthecontinuousinvestmentinfacilitiesfeaturing

the latest technology, leading to reduced energy consumption and

gaseous emissions, the expansion of the use of Natural Gas to

nearly all its premises, thus improving the air quality of the greater

natural environment, and the Group’s commitment to research and

innovation for the utilisation of bauxite residues as rawmaterials.

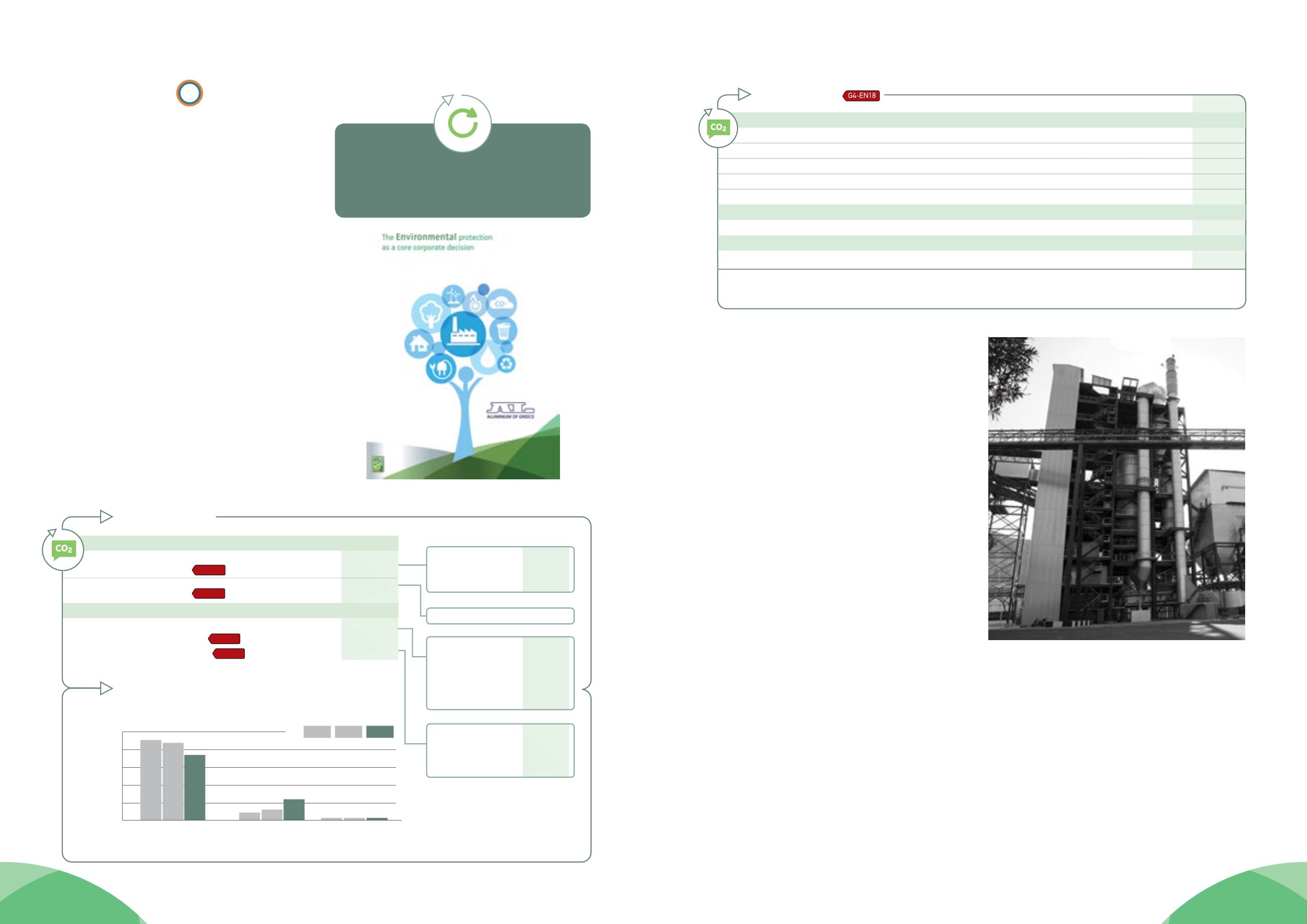

7.1.1 Emissions

The MYTILINEOS Group activity sectors, and especially the

Metallurgy &Mining Sector and the Energy Sector, generate carbon

dioxide (CO

2

) emissions. These are distinguished into direct (Scope

1) and indirect (Scope 2) CO

2

emissions. Direct emissions result

primarily from the aluminiumproduction process (consumption of

fuels and chemical processing as part of the production process)

and secondarily from electricity production (consumption of

natural gas), with indirect emissions corresponding primarily to

the consumption of electricity. In 2016, total direct and indirect air

pollutant emissions stood at 4.67 million tonnes, which was 15.1%

higher than the 2015 figure. This was mainly due to the Energy

sector, where the production of electricity by the Group’s thermal

plants was increased.

Like most high energy-intensive industries, MYTILINEOS Group

produces air emissions that contribute to climate change. The

Group’s actions to stabilise CO

2

emissions are of substantial

importance because they support its operational efficiency. In

this context, the Group monitors CO

2

emissions, on a monthly

basis and implements timely corrective actions in order to

ensure that its annual carbon dioxide emissions are in line

with the legal restrictions and, most importantly, are kept at the

lowest possible level.

Also, MYTILINEOS Group comes under and complies fully with

the applicable regulatory framework and the allowances of the

European Union’s Emission Trading System (EU ETS), as well as

with the restrictions of the EU regulatory framework in force on

large combustion plants.

In the Metallurgy & Mining sector, we have set specific targets that

help stabilise CO

2

emissions during aluminium production. More

specifically, primary-cast aluminium is obtained from alumina

through electrolysis. This process produces carbon dioxide,

fluorine emissions and perfluorocarbons (PFCs). ALUMUNIUM of

GREECE controls these particular emissions through its constant

efforts and appropriate technical interventions. Also, the extension

of the use of natural gas to virtually all company installations haw

minimised the use of fuel, thus improving air quality in the wider

area of the plant.

Additionally, continuing its business investments that benefit

the environment, MYTILINEOS Group launched a new, modern

alumina calcination plant (November 2016), with a nominal

production capacity of 1,350 t per day. This asset replaces the

previous, technologically outdated, high thermal consumption

unit. In addition to the great advantages it offers in terms

of flexibility in production, this project is also expected to

significantly reduce energy consumption and carbon dioxide

emissions. Specifically, it is expected to bring about a

25%

decrease in energy consumption and a reduction of emissions

by approximately 20,000 tonnes of CO

2

and 15 tonnes of NOx per

year. A decrease is also expected in the emission of particles by

80-85%, which corresponds to 30-35 tons per year.

*

The volume of Scope 3 emissions refers only

to the EPC Projects sector, with the exception of

business travel, which also includes the

performance of the Energy sector.

2015

2016

4,058,973.6

3,793,740.7

TOTAL

4,674,616.8

1,666,371.3

2.,392,602.3

2014

1,489,015.2

2,304,725.5

Other indirect CO

2

emissions

(Scope 3)*

Other significant emissions

1,619.47

4,998.1

2,868.6

4,238.2

1,185.4

4,866.9

2015

2014

2016

100%

80%

88.3%

91.8%

75.8%

60%

40%

20%

0%

11.5%

8.0%

24.0%

Energy

Sector

Metallurgy &

Mining Sector

0.2%

0.2%

0.2%

EPC Project

Sector

Percentage of emissions

(Scope 1 & Scope 2)

by activity sector

Emissions

(t CO

2

eq)

Direct CO

2

emissions

(Scope1)

Fuels

(CO

2

)

Processes

(CO

2

)

Processes

(PFCs)

Transport

(CO

2

)

1,941,956.9

291,281.2

88,310.5

7,560.0

392.5

558.1

234.8

3,276.9

1,226.3

275.0

88.7

Electricity consumption

SOx

NΟx

Fluorine

Particles

Transportation

of products

(CO

2

)

Business travel

(CO

2

)

Personnel travel

to/from work

(CO

2

)

G4-EN15

G4-EN16

G4-EN17

G4-EN21

2,353,575.6

2,321,041.2

Indirect CO

2

emissions

(Scope2)

* Perfluorocarbons (CF

4

&C

2

F

6

), are gases that contribute significantly to global warming. To illustrate this, suffice to mention that 1 tonne of CF

4

is equivalent to 7,390

tonnes of CO

2

, while 1 tonne of C

2

F

6

is equivalent to 12,200 tonnes of CO

2

. These perfluorocarbons can be reduced by controlling the frequency and duration of the anode

effect during the electrolysis process.

Specific emissions

G4-EN18

In the Energy activity sector, the key objective is to maintain the

efficiency rates achieved in the operation of the thermal power

plants of Protergia, which are among the highest in Greece,

making the best possible use of natural gas as their primary fuel.

To produce electricity, the Group’s thermal plants use natural

gas. This is a fossil fuel that has a lower carbon content compared

to other mineral fuels, does not release SO

2

and particles,

emits less NOx (mainly NO

2

) in exhaust gases compared to the

maximum allowed quantities under the applicable laws, and

produces less CO

2

(by 70%) compared to lignite-fired plants.

2015

2016

Change

METALLURGY & MINING SECTOR

Specific emissions in Bauxite production (t CO

2

/t of bauxite produced)

0.012

0.018

50.0%

Specific emissions in Alumina production (t CO

2

/t of hydrated alumina produced)

0.76

0.53

-30.2%

Specific emissions in Aluminium production (t CO

2

/t of aluminium produced)

14.6

15.3

5.15%

Fluorine emissions (t/y)

243.2

275.0

13.8%

PFC emissions (t CO

2

/y)*

65,909.6

88,310.5

33.9%

ENERGY SECTOR

Specific CO

2

emissions (t CO

2

/TJ of electricity produced)

93.8

95.2

1.2%

EPC PROJECT SECTOR

Specific CO

2

emissions

(t CO

2

/t of processed metal)

4.9

4.4

-10.7%

5

4

7

8

15

20

23

24

27

29

30

28

21

11

22

12

13

3

16

6

14

19