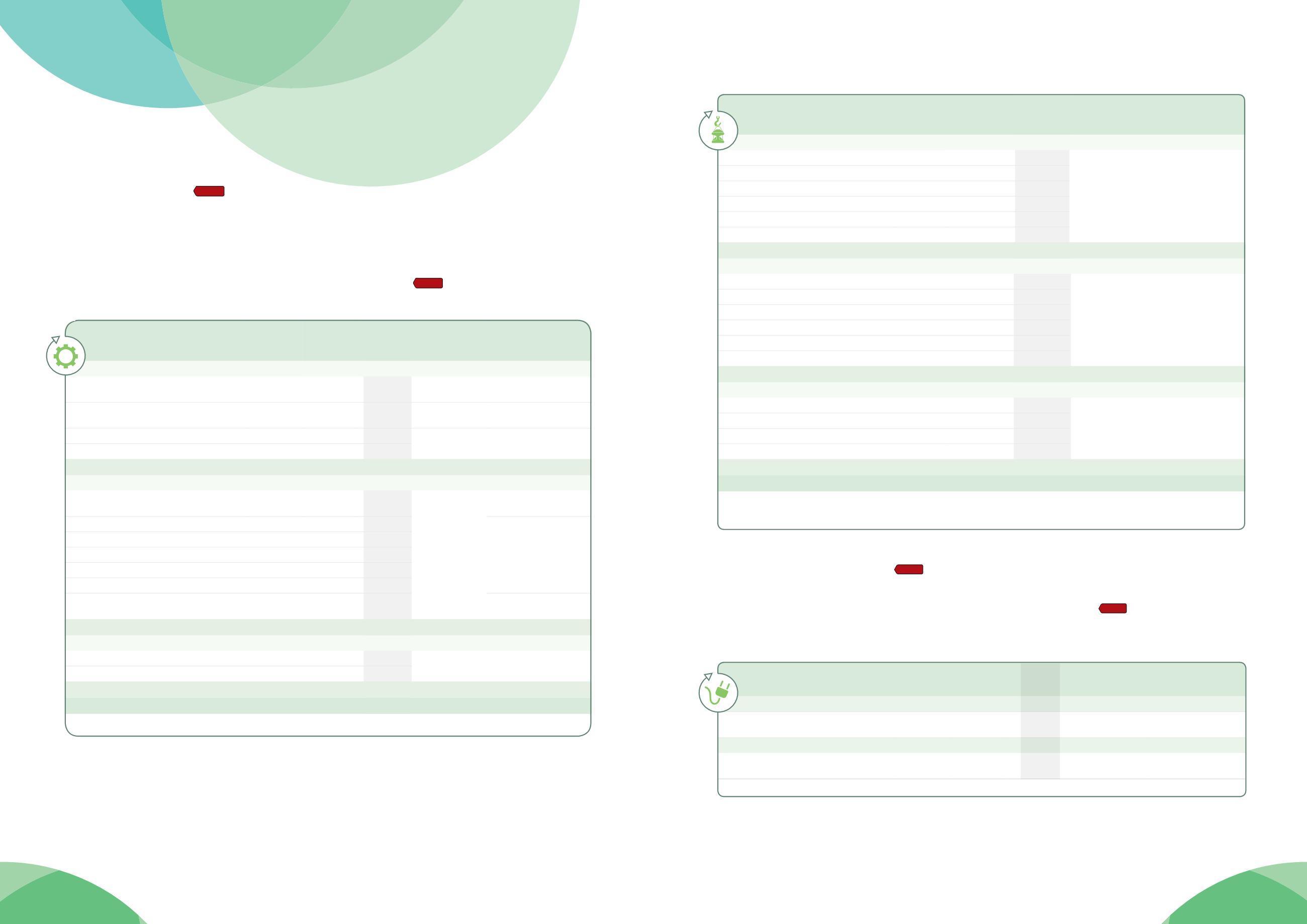

28

29

MYTILINEOS HOLDINGS - SUSTAINABILITY REPORT

2016

METALLURGY & MINING

SECTOR

2014

2015

2016

Measurement

method

Origin of supplies

Type and weight of Raw Materials (tonnes

)*

Bauxite

1,830.996

1,833.201

1,875.509

Direct

measurement

Internal & External

sources

Anhydrous alumina in electrolysis

332,656

345,587

347,882

Estimation

Internal sources or

production

Alloys

2,057

2,473

2,473

Direct

measurement

External supplier

Other metals from third parties

44

0

0

Subtotal (1)

2,165.753

2,181.261

2,225.864

Type and weight of Materials (not incorporated in the end product) (tonnes

)*

Baked anodes consumed in the

electrolysis process

71,949

74,835

75,797

Direct

measurement

Internal & External

sources

Coke

62,210

64,490

64,529

External supplier

Lime

59,388

61,459

60,999

Caustic soda

26,650

22,659

23,516

Tar

13,336

13,296

14,039

Lubricants

132

110

0

Aluminium fluoride

2,668

3,152

3,239

Internal sources or

production

Subtotal (2)

236,333

240,001

242,119

Type and weight of Packaging materials (tonnes

)*

Pine planks

1,016

667

968

Estimation

External supplier

Polyester rings

15

28

0

Subtotal (3)

1,031

695

968

Total (1+2+3)

2,403.117

2,421.957

2,468.951

* From Non-Renewable Sources

In the EPC Projects Sector, we do not manage primary natural

resources, but insteadwe use semi-finished or finished products,

according to the detailed plans/drawings and procedures for each

project, which specify with great accuracy each material which

will be used, its manufacturing method and its exact position and

operation. These plans/drawings and procedures of the Group

conform to the latest developments in the respective fields of

expertise in this specific sector. They involve the use of complex

materials/products such as turbines, power generators, pumps

etc. for incorporation, together with more simple ones such as

merchant bars (beams, pipes, steel plates, axles, cast parts

etc.) for manufacturing (cutting, welding, processing, hardening)

in its industrial facilities or in those of its subcontractors. The

manufactured products are then transported to the customer’s

facility / construction site, where assembly/erection of the final

product (e.g. a power plant) takes place.

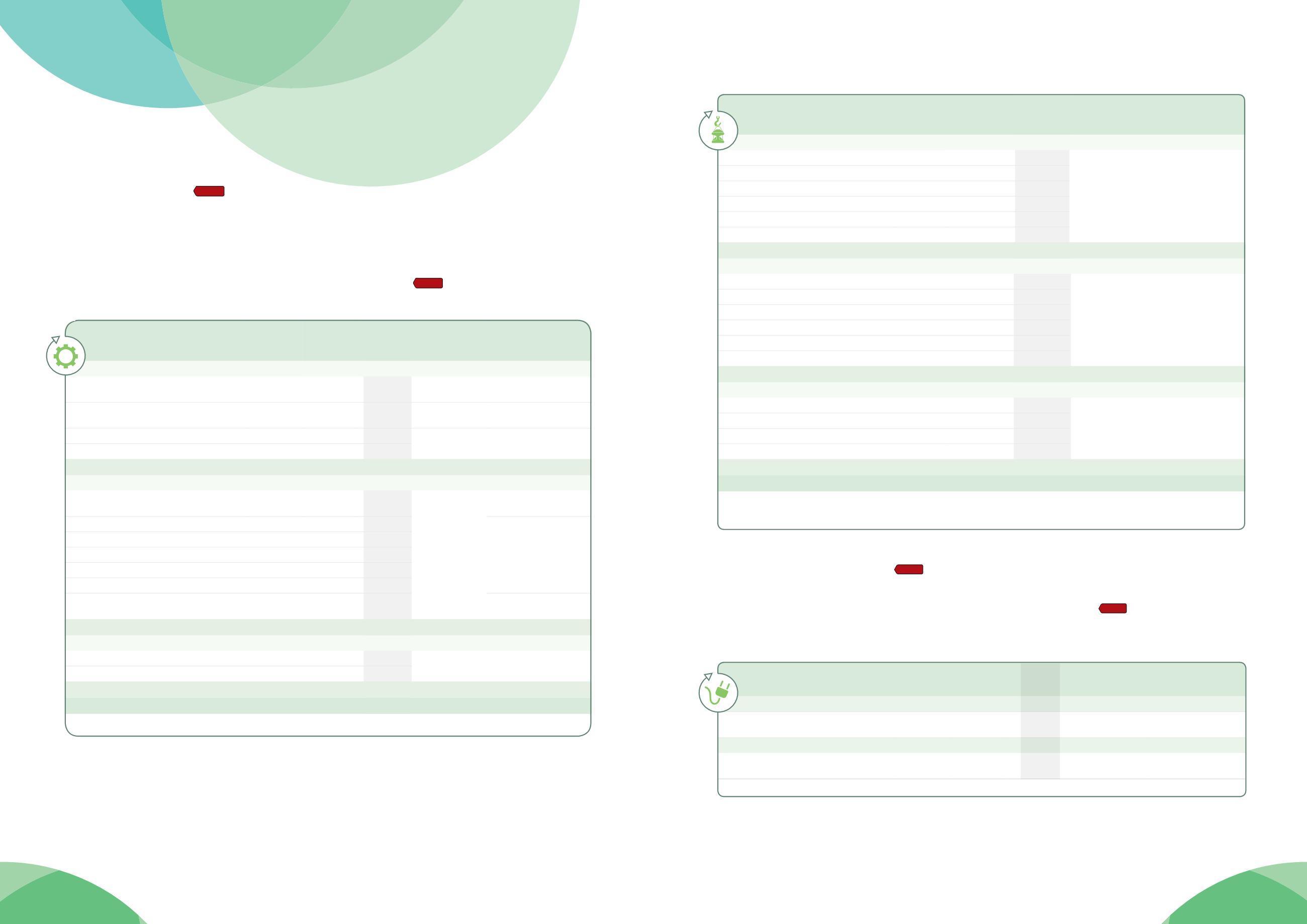

EPC PROJECTS

SECTOR

2014

2015

2016

Measurement method Origin of supplies

Type and weight of Materials (not incorporated in the end product) (tonnes)

Oxygen**

102.5

104.6

103.5

Direct

measurement

External supplier

Welding gases (Argon & Nitrogen)**

81.3

114.7

116.6

Carbon dioxide*

18.2

17.3

22.7

Acetylene*

3.6

5.1

4.1

Liquid coolant*

3.5

5.5

6.9

Mineral oils*

1.5

0.8

1.6

Subtotal (1)

210.6

247.9

255.4

Type and weight of semi-finished products (not incorporated in the end product) (tonnes)*

Steel, in plates / merchant bars

355

226.1

747.5

Direct

measurement

External supplier

Special materials for projects

302

181.2

182.6

Welding materials

21

32.7

24.5

Paints

6

24.8

53.5

Connection materials

5.5

1.5

1.8

Solvents

2

6.4

14.2

Subtotal (2)

691.5

472.9

1024.1

Type and weight of Packaging materials (tonnes

)*

Nylon

2.3

2.3

5.8

Tarpaulin

0.2

0.1

0.4

Cardboard

-

-

1.4

Plastic packaging

-

-

0.1

Subtotal (3)

2.5

2.4

7.7

Total (1+2+3)

904.6

723.2

1,287.2

*From Non-Renewable Sources

** From Renewable Sources

ENERGY

SECTOR

2014

2015

2016

Measurement

method

Origin of supplies

Type and weight of Raw Materials

*

Natural gas (m Nm

3

)

144.9

223.4

507.6

Direct

measurement

External supplier

Type and weight of Materials (not incorporated in the end product)*

Lubricating oils (lt)

8,213.0

8,333.0

17,949.6

Direct

measurement

External supplier

* From Non-Renewable Sources

The percentage of the use of recycled materials, in the

implementation of projects in the EPC Sector,

stood at 35.8%

1

shown an increase by 5.3% compared to 2015.

G4-EN2

Additionally,

a key criterion in the design stage of the projects that METKA

is carrying out as an EPC Contractor, is the maximum use of

recyclable materials. The company’s requests for proposals and

contracts with suppliers of materials and equipment contain a

specific clause regarding their compliance with the requirements

of the ISO-14001 International Standard, specifically referring to

the prohibition of using environmentally hazardous materials and

the obligation to make the maximum possible use of recyclable

materials.

In the Energy Sector, the raw material used in the Group’s

power plants is natural gas, which cannot be recycled and is

not a renewable source.

G4-EN2

The substantial increase in

the consumption of natural gas at the thermal power plants of

PROTERGIA in 2016 was due to the increase in the production of

electricity.

1

Of the 1,024.1 tonnes of total weight of materials used and incorporated in the end products, steel (in the form of plates, merchant bars or other project

materials) accounted for approximately 916.2 tonnes. Around 40% of the EU’s total steel production comes from electric arc furnaces, in which steel is

produced from 100% recycled raw material (scrap)

(Source:

Strasbourg, 11.6.2013, COM (2013) 407 final, p.10).

Thus, 366.48 tonnes (40% of 916.2 tonnes) correspond to recycled steel.

7.2.2 Raw & Other Materials

G4-EN1

In 2016, approximately 2.2 million tonnes of raw materials

(dry basis) were used in the Metallurgy & Mining sector for the

production of primary cast aluminium products, showing just

a marginal increase (by 0.7%) compared to 2015. The 85% of

this quantity relates to bauxite, which comes mainly from the

exploitation of mines in the prefectures of Fokida and Viotia and

is the main raw material used for the production of alumina and

aluminium. The remaining 15% relates to other materials from

non-renewable sources. The use of alternative raw materials,

i.e. byproducts or waste of other industries, which can reduce

the consumption of raw materials, is not applicable to aluminium

production process.

G4-EN2

Direct

measurement

External supplier