38

39

MYTILINEOS HOLDINGS - SUSTAINABILITY REPORT

2016

8.1 Occupational Health & Safety

TheHealthandSafety of employeeshas always been fundamental

to the operation of MYTILINEOS Group. As a responsible

organisation, the Group acknowledges its responsibility to

ensure the best possible Health & Safety conditions in all its work

areas, as well as the employees’ right to work without exposing

themselves to any risk of injury or illness.

Health & Safety Performance

MYTILINEOS Group Personnel.

In 2016, the Group’s primary objectives regarding zero fatalities

and occupational disease incidents regarding the directly

employed personnel were achieved. On the contrary, compared

to 2015, the rate of accidents (Injury Rate – IR) rose from 0.17 to

0.21. Although this is still consistent with the low levels of the last

five years (0.19 on average), the Group’s efforts to further reduce

this trend will be intensified in 2017.

MYTILINEOS Group Policy on

Occupational Health & Safety:

Management system and regulatory compliance

All Group subsidiaries apply an Occupational Health &

Safety Management System certified in accordance with

the OHSAS 18001 International Standard in all work areas.

This system is designed to minimise risk, by allowing

the continuous adoption of measures to prevent and

minimise accidents and occupational diseases, providing

for ongoing employee training and strengthening a safe

work culture.

Additionally, in full compliance with the relevant European

and national laws, the Group applies all required

measures to ensure the health and safety not only of its

employees, but also of external associates and visitors to

the premises and construction sites of its various activity

sectors.

.

OHSAS

18001

O

C

C

U

P

A

T

I

O

N

A

L

H

E

A

L

T

H

&

S

A

F

E

T

Y

2014

0.18

0.21

0.00

9.35

10.67

0.00

2013

0.28

0.29

0.35

12.80

13.20

10.3

2015

0.17

0.19

0.00

1.45

1.65

0.00

2016

0.21

0.24

0.00

5.93

6.74

0.00

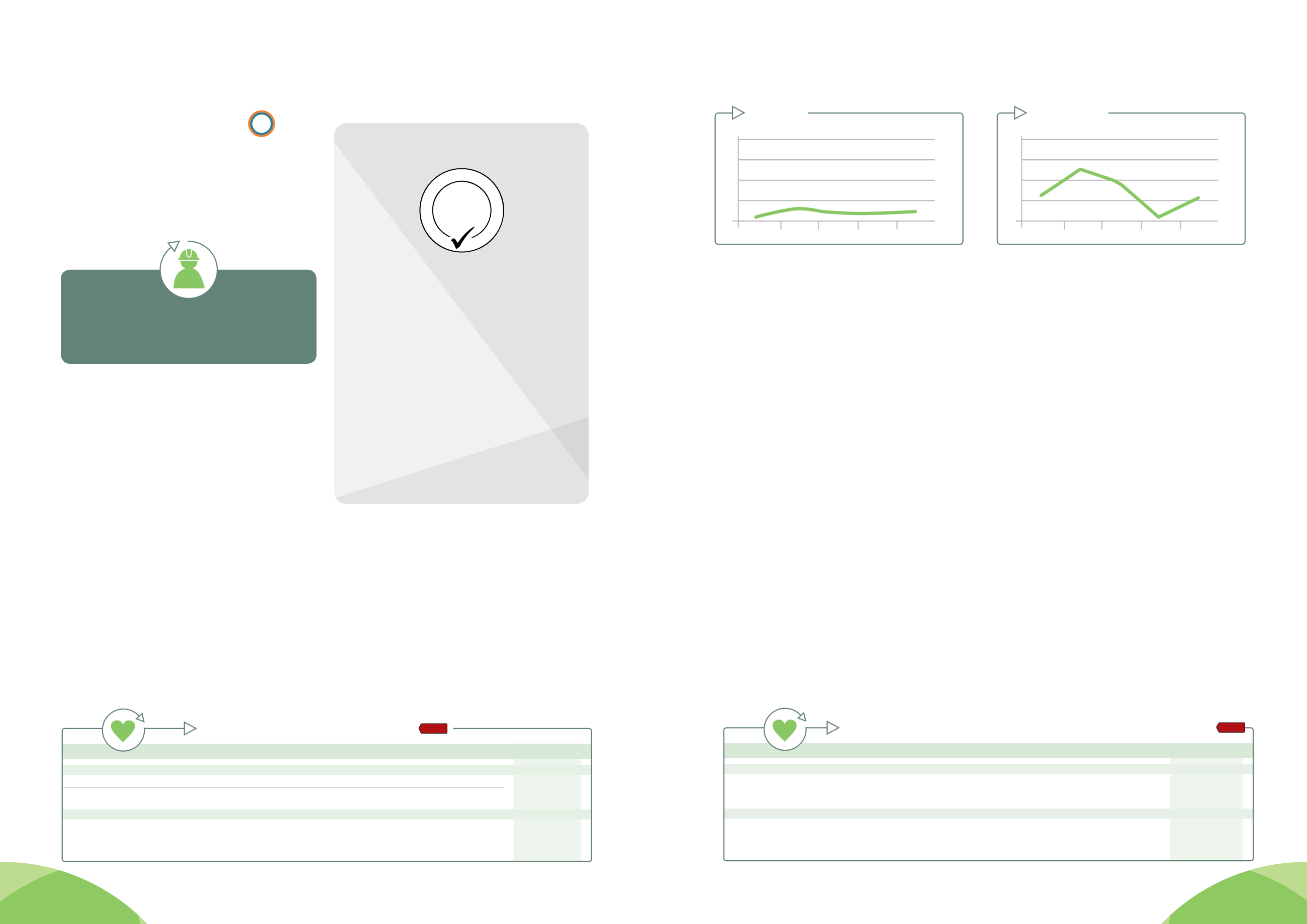

Health & Safety Indicators (Group Personnel)

Injury Rate

per 200,000 hours worked (IR)

Lost Days Rate

per 200,000 hours worked (LDR)

2

20

G4-LA6

Injury Rate (IR)

IR (Total)

IR (Men)

IR (Women)

Lost Days Rate (LDR)

LDR (Total)

LDR (Men)

LDR (Women)

2016 Highlights

• In 2016, there were 5 lost-time injury incidents (direct

employees) compared to 4 incidents in 2015.

• Despite the efforts made in the area of safety, there was

one fatality in the Metallurgy & Mining sector, involving an

employee of an independent contractor providing its services

to the mining process.

•

27.878

man-hours were spent on training, focusing on the

development and maintenance of an accident prevention

mentality.

• The campaign tailored to the Metallurgy & Mining activity for

the promotion of safety at the workplace using the innovative

method of activating the brain’s “right hemisphere”, was

continued for the second consecutive year.

• Absenteeism rates were low across all Group activity sectors,

ranging from a maximum of

2.7%

to a minimum of

0.4%

of the

total number of scheduled work days.

• Further improvements in the incorporation of contractors’

personnel in the Health & Safety management system in the

Metallurgy & Mining sector.

5

1

4

7

8

9

17

15

20

23

24

25

26

27

29

30

28

21

10

11

22

12

13

2

3

18

16

6

14

19

In 2016, five (5) accidents occurred in total (male employees).

More specifically:

• In the Metallurgy and Mining Sector, two (2) accidents occurred,

resulting in a total loss of 115 working days.

• In the EPC Projects Sector, two (2) accidents occurred, resulting

in a total work time loss of 19 days.

• In the Energy Sector, 1 accident occurred, resulting in a total

work time loss of 7 days.

Four of the accidents involved limb injuries and one accident involved

electrocution. All incidents were investigated thoroughly and analysed

using the “Root Cause Analysis” method, the results were understood

and, at the same time, corrective measures were taken, with the aim

of preventing any conditions which could cause the reoccurrence of

such incidents. In what in particular concerns the Metallurgy &Mining

Sector, the Group evaluates its performance against the performance

of similar plantsand intensifies itsefforts for continuous improvement.

The investigation of accidents shows the need for a comprehensive

assessment of the risks present at the workplace. In this respect,

ALUMINIUM OF GREECE already applies procedures for recording

and investigating

potential serious and non-serious safety incidents

which, under certain circumstances, could lead to accidents. The

annual findings are used to improve the procedures of safe attitude,

the equipment and the training provided.

Additionally, matters related to health and hygiene are key to the

quality of life of employees and of the communities in which we

operate. The Group has been consistently investing in this area,

especially in the Metallurgy and Mining Sector, where all factors in the

work environment are being monitored, assessed and controlled, on

the basis of Health & Safety risk assessment reports, in an effort to

constantly improve the good health of employees and ensure healthy

living conditions at the workplace.

Exposure to dust, noise, high temperatures and to substances such as

fluorine compounds, sulphur dioxide, carbon monoxide and aromatic

polycyclic hydrocarbons, are themain factors currently monitored.

Finally, in order to constantly improve the health of employees,

the occupational physicians help promote a healthy lifestyle at the

workplace, while the Group offersmedical care plans, over and above

theminimumprovisions of the law.

Personnel of independent contractors.

Managing the safety of employees of independent contractors is a

particular challenge. MYTILINEOS Group is consistent in its efforts

in this area and focuses on the need to change everyone’s attitude

and behaviour with regard to accident prevention. However, seven

(7) lost-time injury incidents were recorded in 2016, while the one

fatality that occurred in the Metallurgy and Mining Sector confirmed

the fact that no effort can be regarded as sufficient. At the same time,

this particular incident acted as a reminder of the unpredictability of

the human factor, demonstrating that everyone at the workplace

must be vigilant at all times, so that risks at the workplace are

prevented and eliminated on time and the zero accidents target is

achieved.

- The number of accidents includes fatalities and incidents causing

interruption of work.

0.21

0.00

9.35

10.67

0.00

0.29

0.35

12.80

13.20

10.3

0.19

0.00

1.45

1.65

0.00

0.24

0.00

5.93

6.74

0.00

Injury Rate

per 200,000 hours worked (IR)

Lost Days Rate

per 200,000 hours worked (LDR)

2012

2013

2014

2015

2016

1.5

2

20

1

0.1

0.28

0.18

0.17

0.21

0.5

2012

2013

2014

2015

2016

15

10

6.4

5.9

12.8

9.3

1.4

5

- Days lost due to accidents are calculated starting on the day after the

incident and refer to scheduled work days.

IR (Men)

IR (Women)

Lost Days Rate (LDR)

LDR (Total)

LDR (Men)

LDR (Women)

2016

2015

2014

0.45

0.46

0.00

7.76

7.85

0.00

0.37

0.38

0.00

4.47

4.54

0.00

0.49

0.50

0.00

6.91

7.07

0.00

Health & Safety Indicators (Personnel of the Group's independent contractors)

G4-LA6

Injury Rate (IR)

IR (Total)

IR (Men)

IR (Women)

Lost Days Rate (LDR)

LDR (Total)

LDR (Men)

LDR (Women)

All the accidents involved male employees and each one of them

resulted in an interruption of work for three or more days. The

immediate actions taken after the accidents involved the provision of

medical care, consisting in theadministrationof first aidat theproject

site and the transport of the injured employee to an associated

hospital for further treatment. The main corrective actions taken,

considering that there is always room for improvement, were the

following: (a) Employees were provided with relevant training, (b)

additional work instructions were issued, and (c) greater emphasis

was given to proper monitoring and control.