45

S U S TA I NAB I L I T Y R E PORT 2 0 1 2

During 2012, we continued our efforts

to develop and incorporate into the

operations of all Group companies a

“Safe Work Rule” attitude and ap-

proach that focuses on the prevention

of accidents and occupational dis-

eases. Every year, our goal is to have

zero serious accidents or work-related

fatalities and zero incidents related to

occupational diseases. An additional

future goal is to include the achieve-

ment of Occupational Health & Safe-

ty targets as a specific criterion in the

evaluation of the Management Exec-

utives of our subsidiaries, in order to

emphasise even more their responsi-

bility for combining business priorities

with Corporate Social Responsibility in

every respect.

Our performance in 2012 was marked-

ly improved compared to the previous

year, as only two (2) injuries were

recorded. In addition, there were no

work-related fatalities and no inci-

dents related to occupational dis-

eases.

This improved performance was made

possible by several key initiatives in our

subsidiaries, as follows:

PROTERGIA S.A.:

The company in-

tensified its actions to prevent injuries

and occupational diseases at the

workplace, by adopting the OHSAS

18001 International Standard for its

Occupational Health & Safety Man-

agement System and obtaining the

relevant certification in late 2012.

The company’s training plan for

2012 included training on emer-

gency response procedures, focusing

on fire-fighting and the evacuation

of facilities.

METKA S.A.:

The company pro-

vided training on Health & Safety to

all newly-hired Personnel, as part of

its formal induction programme (ap-

plied in the company’s Offices /

Construction Sites / Manufacturing

Plants), which new employees attend

before they commence work. Reg-

ular training updates on Health &

Safety issues were provided to all

company personnel, with a focus on

the particular characteristics of each

specific work environment e.g. (Evac-

uation Drills, Fire Safety, Health and

Safety in construction sites or man-

ufacturing plants).

ALUMINIUM S.A.:

The company

carried out the following actions dur-

ing the year: 60 Personal Safety Ac-

tions (PSAs) and 10 Management

Safety Visits (MSVs) for every man-

agement executive who received

relevant training; 18 Health and

Safety Visits; 10 inspections of sub-

contracts in progress; 8 inspections

of confined spaces; 15 installation

lockout inspections; and 12 circula-

tion inspections. In addition, the

company monitors the following

Safety indicators: LTI (Lost Time Injury

– number of accidents with inter-

ruption of work); RCR (Recordable

Case Rate – number of recorded ac-

cidents without interruption of

work); and FA (number of visits to

the Medical Station). For every inci-

dent recorded, the Incident Analysis

Rate (using the “Cause Tree Analy-

sis” method) and the 48-hrs Safety

Incident Analysis Rate are also

logged. Finally, 185 measurements of

safety conditions (noise, vibrations,

presence of fluoride etc.) and 743

regular employee medical check-

ups were carried out, and 310 em-

ployees were tested for the presence

of fluoride in their body.

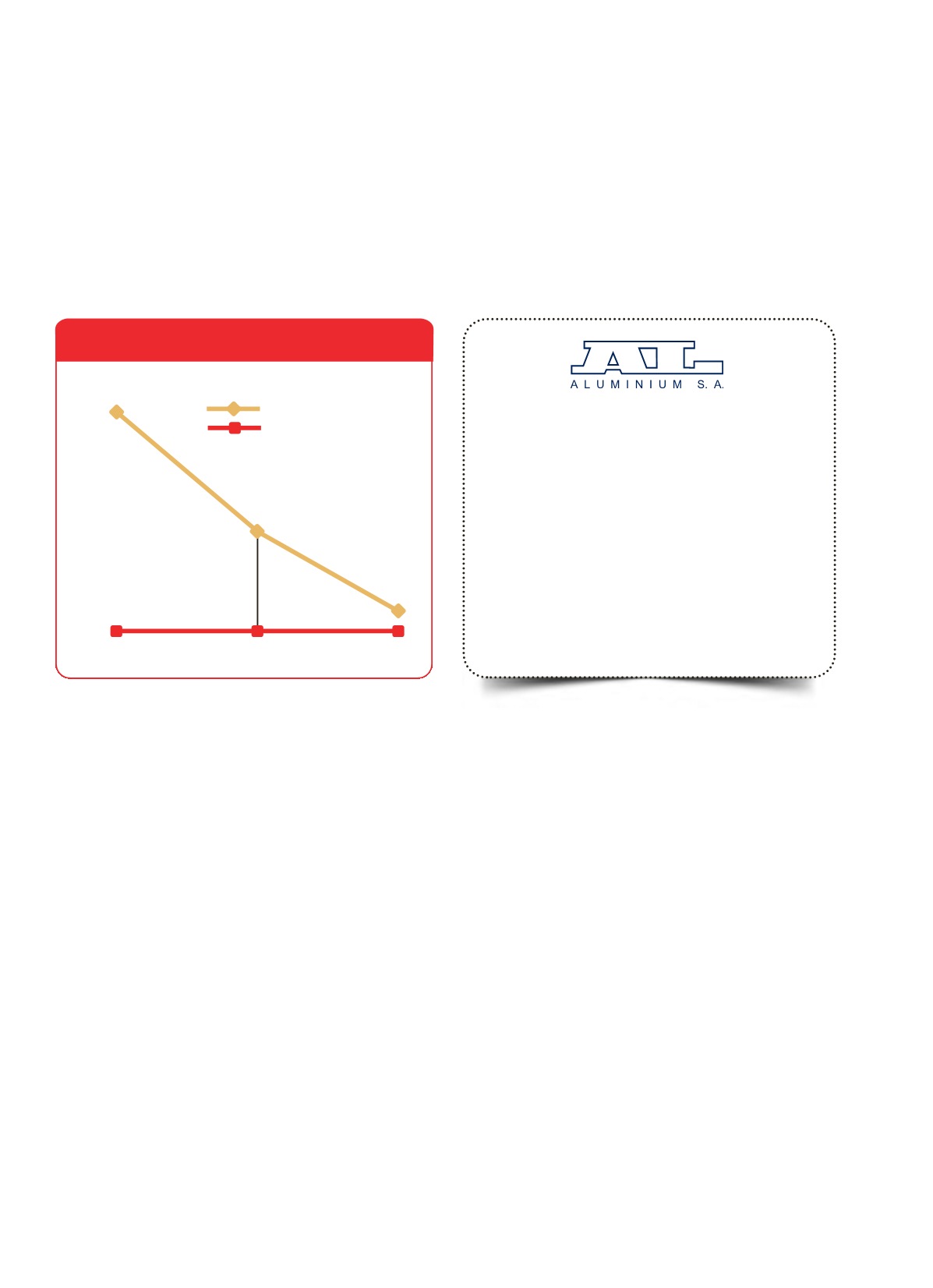

0,0

5,0

10,0

15,0

20,0

2010

2011

2012

25,0

Accidents

Work-related Fatalities

22

10

During 2012 two accidents occurred leading to

temporary interruption of work. These involved

injuries in the limbs (legs) sustained by employees in

the Alumina production department. The two

incidents were analysed using the “Cause Tree

Analysis” method, the reasons that caused themwere

established, and relevant corrective actions were

planned (including, for each action, the designation

of a person in a charge, a deadline and a completion

date), with a view to informing employees and to

preventing the occurrence of any conditions that

could cause such accidents to happen again.

Rate of Accidents and Work-related Fatalities

2

6.3 Occupational Health & Safety