59

S U S TA I NAB I L I T Y R E PORT 2 0 1 2

Our efforts regarding the rational

management of raw and other ma-

terials focus on the identification and

specification of suitable methods,

which will allow our subsidiaries to al-

so use recycled materials in process-

ing and manufacturing of their prod-

ucts. The maximum possible use of re-

cycled materials in our production

processes will help reduce demand for

virgin materials, maintain the level of

mineral resources and reduce total op-

erating costs in our Group. Today, the

percentage of the use of alternative

raw materials in MYTILINEOS Group,

especially in aluminium production

and in construction, does not exceed

20%.

On the other hand, a particularity of

the Energy sector is that the raw ma-

terial used to drive our electricity

production plants is natural gas,

which cannot be recycled and is not

a renewable source.

During 2012, a total of 2.37 million

tons of raw and other materials were

used to produce the Group's end

products, down by 5.2% from the

quantity used last year. The largest part

of this quantity came from the mining

activity and involved the consumption

of bauxite in aluminium production.

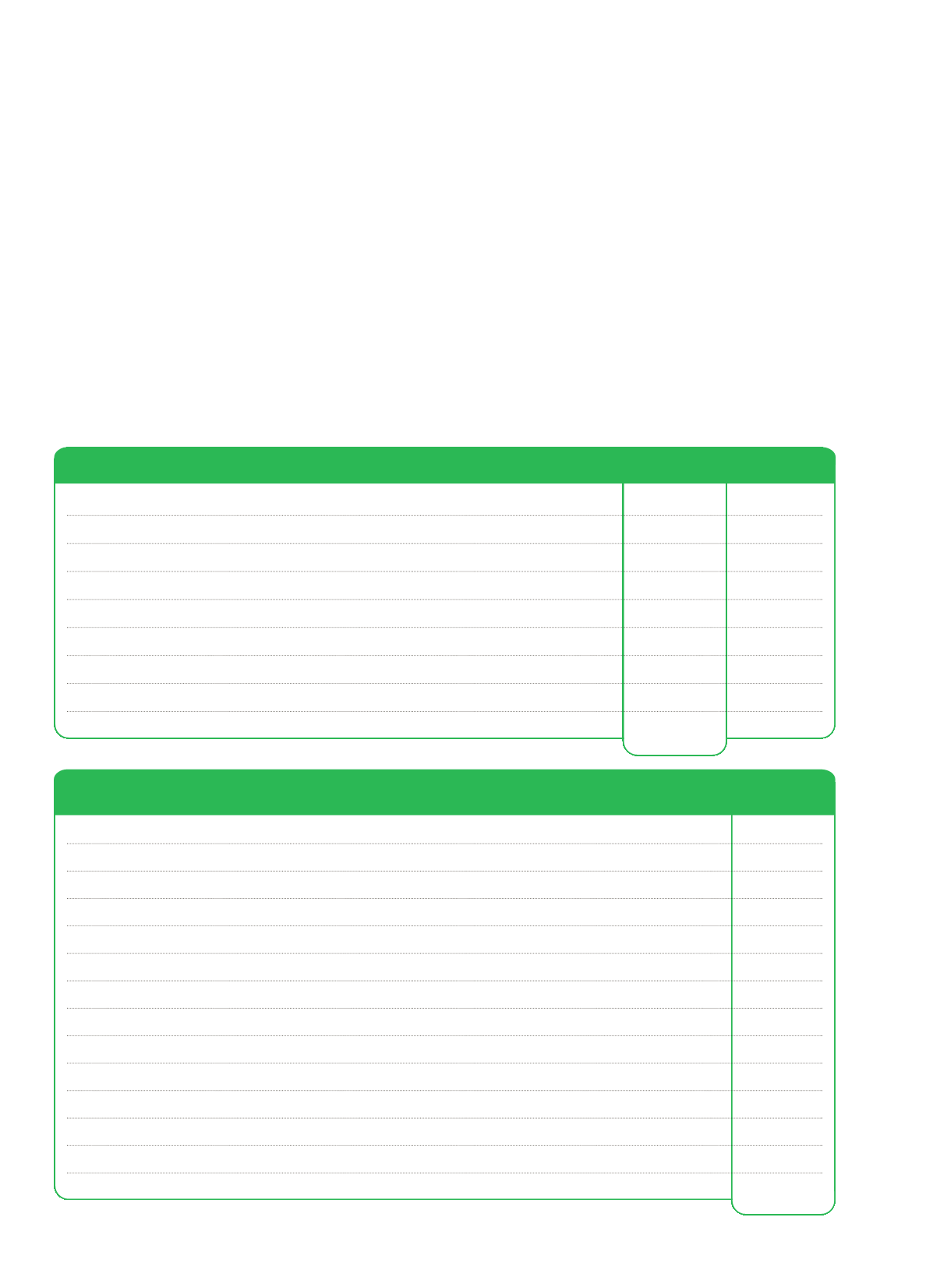

8.2 Management of raw & other materials

Raw materials

2011

2012

Change

Bauxite (t)

1,816,912.0 1,745,940.7

-3.9%

Limestone (t)

118,579.0

54,363.0

-54.1%

Anhydrous alumina for electrolysis (t)

317,082.0

317,911.7

+0.3%

Other metals from third parties (t)

3,194.0

291.9

-90.8%

Alloys (t)

145.0

157.5

+8.3%

Oil - fuels (lt)

1,247,706.0 1,319,134.0

+5.7%

Petrol – fuels (lt)

36,351.0

33,949.0

-6.6%

Electricity (kWh)

3,791,533.0 3,440,762.0

-9.2%

Natural gas (TJ)

7,671.6

27,160.3

+254.0%

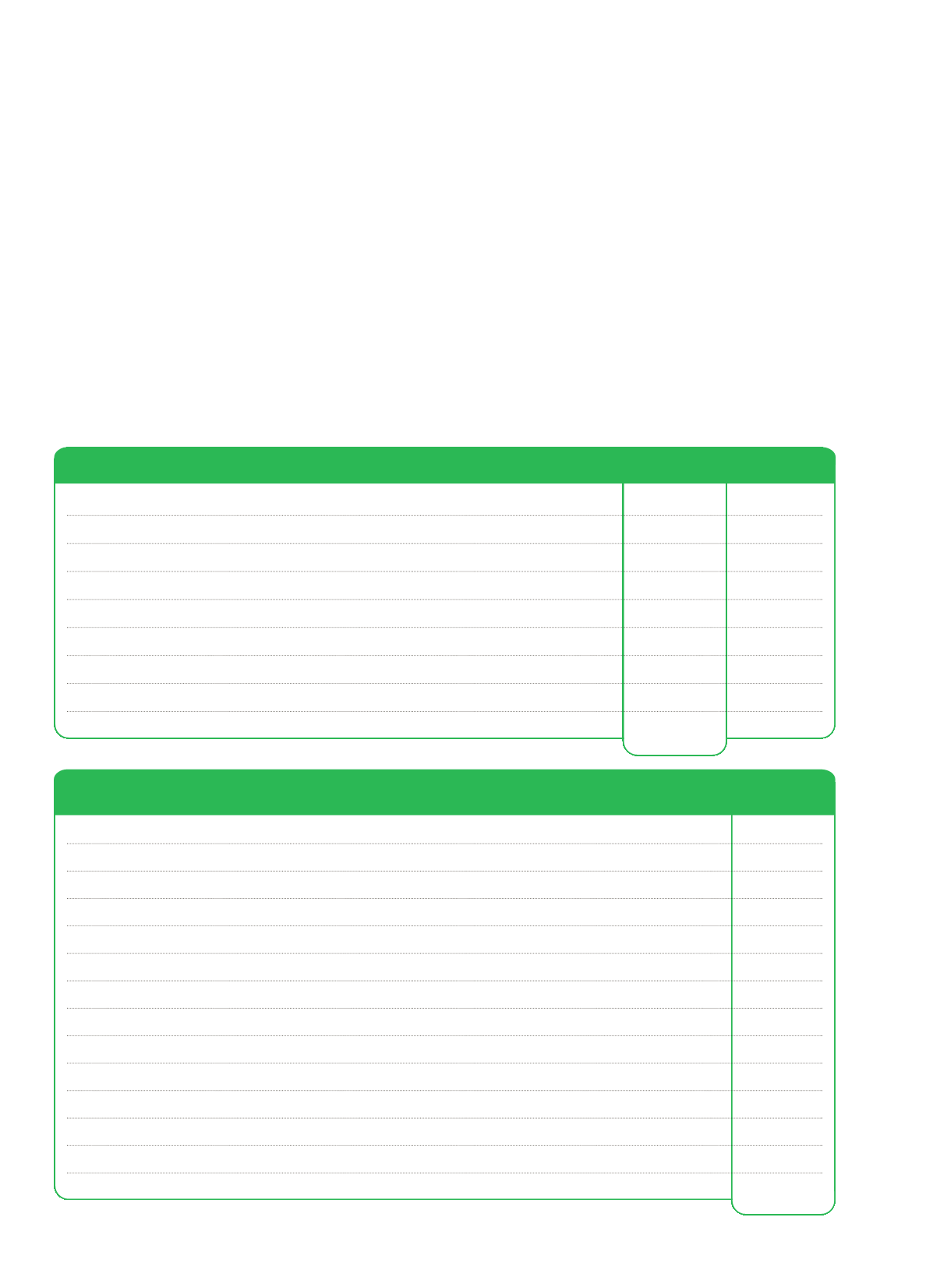

Materials used but not incorporated in the end product

2011

2012

Change

Caustic soda (new soda) (t)

26,293.0

25,451.0

-3.2%

Calcium oxide (lime) (t)

66,760.0

66,397.0

-0.5%

Lubricants (t)

102.0

117.4

+15.0%

Tar (t)

14,578.0

15,000.3

+2.9%

Coke (t)

65,336.0

75,038.5

+14.8%

Aluminium fluoride (t)

2,644.0

3,182.0

+20.3%

Baked anodes consumed in the electrolysis process (t)

68,972.0

70,193.1

+1.8%

Mineral oil (t)

1.9

1.7

-10.5%

Liquid coolant (t)

3.9

3.6

-7.7%

Oxygen (t)

193.0

118.0

-38.8%

Acetylene (t)

4.9

4.1

-16.3%

Carbon dioxide (t)

24.0

27.9

+16.2%

Argon & Nitrogen (t)

76.0

76.8

+1.0%

Lubricating oils (t)

12.7

12.1

-5.0%