67

S U S TA I NAB I L I T Y R E PORT 2 0 1 2

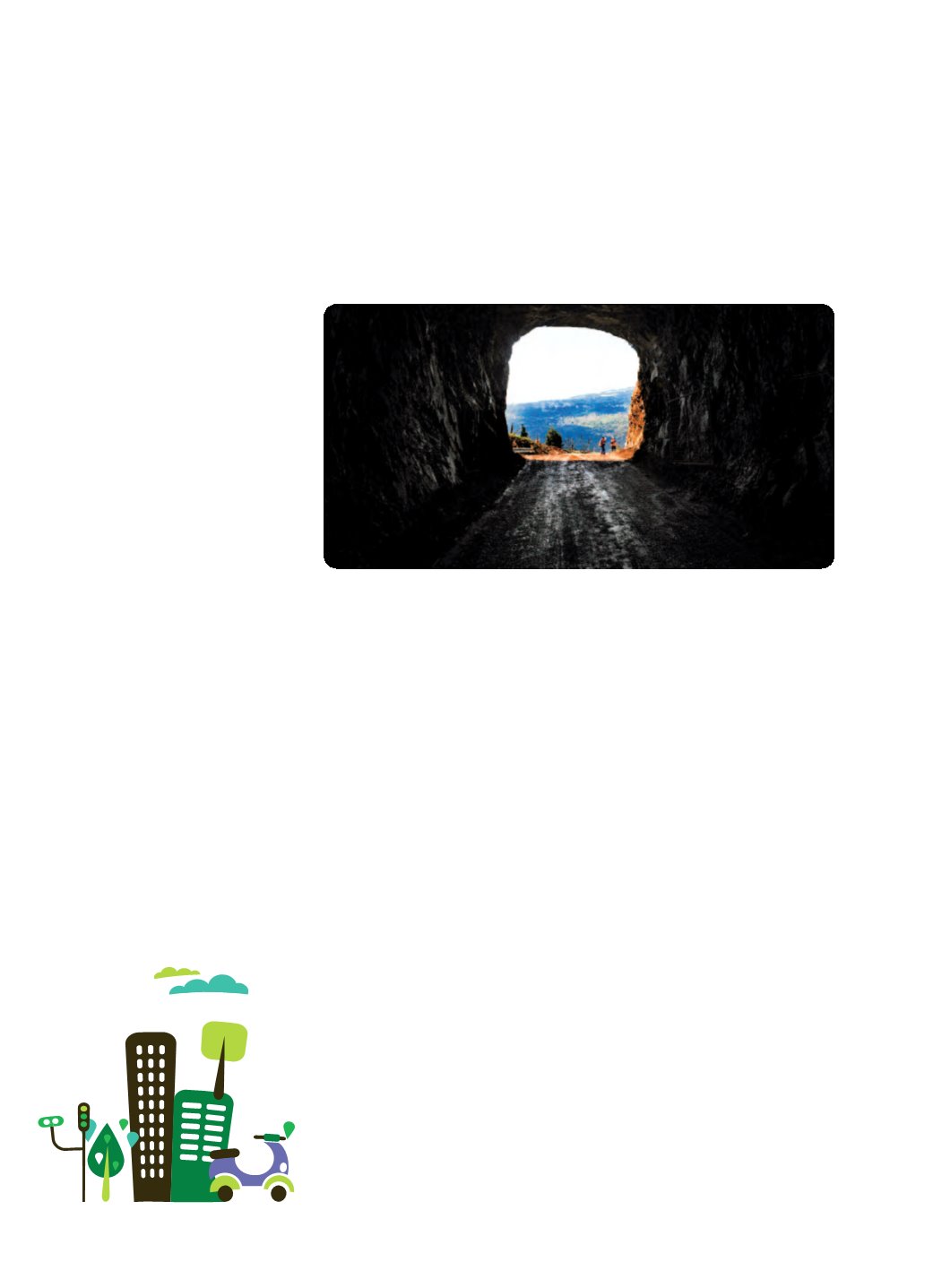

8.6 Significant spills

During 2012 a total of 27 incidents

were recorded in DELPHI-DISTOMON

S.A. involving spillage in the soil in un-

derground tunnels, due to the break-

down of machinery, of lubricants

weighing nearly 3.5 tons, a quantity re-

duced by 30% from the corresponding

one for 2011. The company respond-

ed immediately, dealing with the in-

cidents and collecting the contami-

nated soil. No high or medium gravi-

ty environmental pollution incidents

occurred and no incidents were re-

ported involving the spillage of haz-

ardous materials to the environment

by any other Group company.

primary fuel to produce electricity

and by using Combined Cycle Ther-

mal Power Plants (CCGTs) and High

Efficiency Combined Heat and Pow-

er (CHP/High Efficiency CHP) with a

total production capacity of 1,200

MW, which introduce Best Available

Techniques (BATs) and, because of

their flexibility and high efficiency,

contributes towards the reduction

of greenhouse gas emissions. In

Renewable Energy Sources,

PROTERGIA S.A. is already produc-

ing electricity from Wind farms (36

MW in operation), Photovoltaic

plants (11.5 MW in operation) and

small Hydropower plants (6 MW in

operation) and is developing a

1,400 MW portfolio of RES assets in

various licensing stages.

These investments will also sub-

stantially contribute to the efforts

for achieving of the 20-20-20 target

for Greece.

In the EPC sector, METKA S.A. is

planning to replace oil with natural

gas as the fuel used in its Plants and

Offices, to use company cars with

new, low-emissions technology, and

to replace Freon in its refrigerating

machinery with new technology

cooling agents.

We also intend to explore the

prospects regarding the application

of the innovative Carbon Capture

and Storage (CCS) technology.

8.7 Waste management

The efforts to optimise the manage-

ment and utilisation of our waste are

based on the principles of waste min-

imisation and proper disposal. The key

goals of MYTILINEOS Group are to re-

duce the quantity of waste disposed

in landfills and at sea, and to increase

in parallel the use of recycling.

In managing its solid waste,

MYTILINEOS Group follows a clearly

defined procedure with specific stages,

summarised below:

Waste production:

Refers to the

stage where certain types of solid

waste are designated as undesirable

and the decision is taken either to

throw them away or to collect

them for disposing of them centrally.

Sorting of materials for recycling or

recovery takes place at this stage.

On-site management (storage):

During this stage, the future of

waste is decided. On-site storage is

of primary importance because of

aesthetic and public health reasons,

but also because of the financial cost

to the companies.

Collection:

During this stage, waste

are collected and loaded onto their

transport means (usually a vehicle),

for transport to a transfer station,

treatment location or disposal area.

Transport:

Refers to the stage

where waste is transported to a

transfer station and from there to

the treatment location or disposal

area.

Treatment/recovery:

During this

stage, a variety of processes and

equipment are used to either utilise

waste itself by improving certain

characteristics or to obtain useful in-

gredients/components or energy.

Disposal:

This stage refers to the fi-

nal disposal of waste.

During 2012 we permanently dis-

continued the disposal of bauxite

residues at sea. The quantity of non-

hazardous waste disposed through re-

cycling increased by 35% from last

year, and the quantity of waste dis-

patched to Landfills, primary from

aluminium production, increased by

22%.