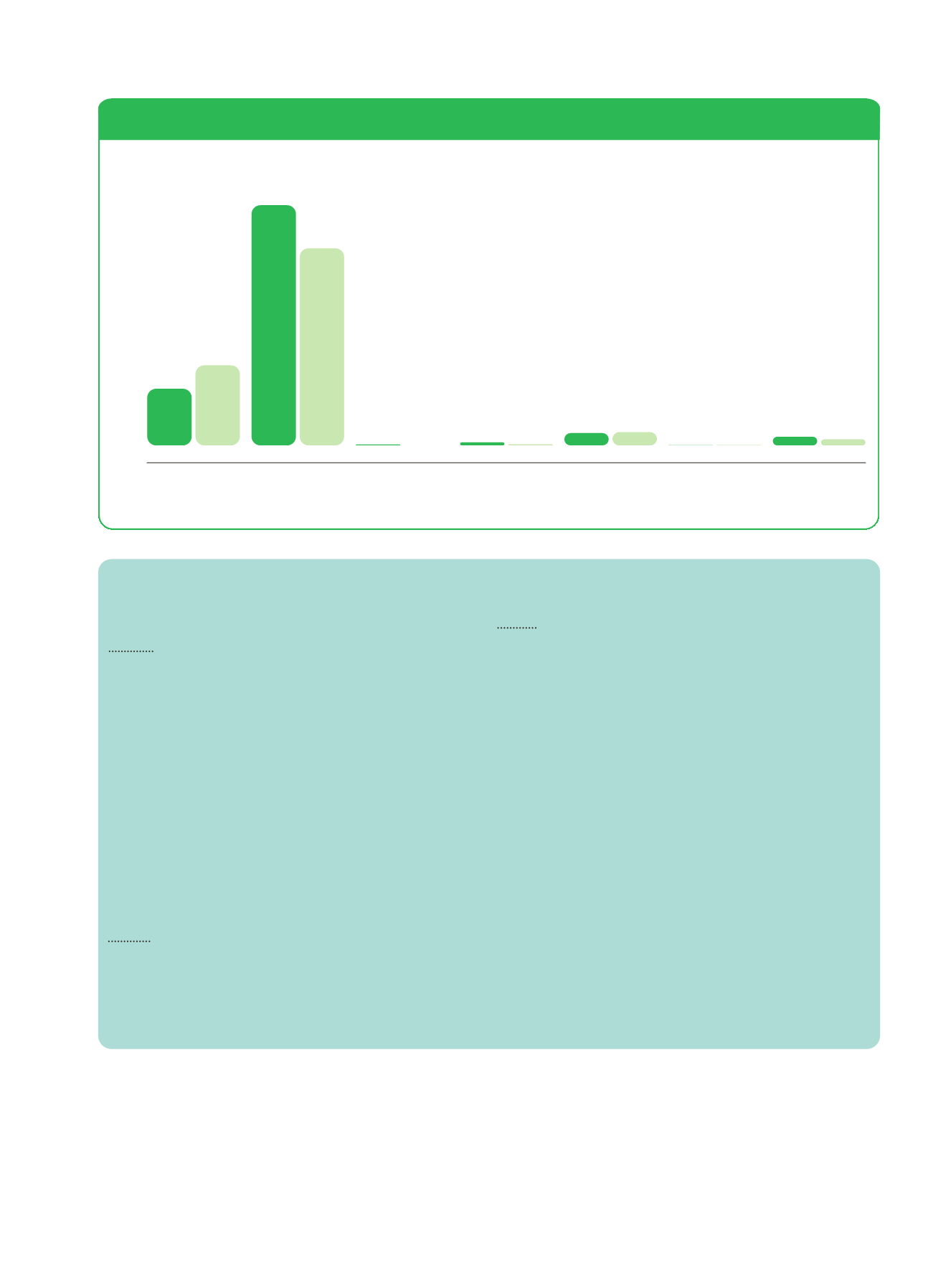

Other significant air emissions (ton)

66

0

1,000

2,000

3,000

4,000

5,000

1,023.0

1,444.5

16.1 2.7 57.7 19.2

222.9 239.2

5.1 7.4 157.7 110.1

4,330.5

3,553.9

Nox

Sox

N

2

0

CH

4

Fluoride

emissions

PFC’s

Particles

2011

2012

Calculation methods for ΝΟx, SOx and Dust emissions

Nevertheless, the environmental strat-

egy of MYTILINEOS Group comprises

key initiatives that focus on improv-

ing our performance relating to green-

house gas and CO

2

emissions over the

next years. These include the follow-

ing:

The most extensive possible use of

natural gas as the primary fuel in-

stead of oil in aluminium production,

with ALUMINIUM S.A. already mak-

ing efforts to optimise the use of

lime (purchase/production).

In the Energy sector, PROTERGIA

S.A. by selecting natural gas as the

In the Metallurgy sector (aluminium production):

Α. Dust:

Dust concentration in the plant’s point emission sources is meas-

ured as follows: (a) By isokinetic sampling, with a frequency of four

samplings per year at the plant’s Α070, FLN, H15, H1, H28 chim-

neys; (b) using continuous measurement analysers at the anodes

kiln, revolving and static components and lime kiln furnaces; and

(c) by isokinetic sampling, with monthly samplings at the no. 1-2

and no.3-4 Gas Treatment Centres for the electrolysis gases. For

calculating the quantities of annual emissions in tons, the following

were used: (a) For point sources where isokinetic sampling is used,

the average of the four concentration values (in mg/Nm3) and of

the flow rate (in Nm3/s); and (b) for point sources where contin-

uous measurement is used, the average of the daily concentration

values (in mg/Nm3) and of the flow rate (in Nm3/s) from the iso-

kinetic samplings of all years for which these are available.

Β. ΝΟx:

Annual emissions of nitrogen oxides refer only to fuel consump-

tion (fuel oil) and were calculated stoichiometrically, using an emis-

sion factor of 5.363 g/kg of fuel (Guide to Energy Investments, Min-

istry of Development, 2005). NOx emissions from processes are not

measured or calculated (no official method is available yet).

C. SO

2

:

Annual sulphur dioxide emissions refer only to fuel consumption

(fuel oil) and are calculated based on its sulphur content as this is

shown on the chemical analysis sheets. Sulphur dioxide emissions

from the anodes baking process are not calculated (no verifiable

method is available).

In the Energy sector:

In the case of the power production plants of PROTERGIA S.A., be-

cause of the quality of the consumed fuel (natural gas), no emis-

sion limit values apply for SO

2

and particle emissions (in accordance

with the Environmental Terms Approval Decisions in force for these

plants, and under the applicable Community and Greek law on air

emissions from combustion plants). Consequently, emission limit

values only apply for NOx (in this particular case, NO

2

) with the fol-

lowing acceptance limits:

- 50 mg/Nm3 (on a dry basis with 15% Ο

2

), for operation with a

load above 70%;

- 75 mg/Nm3 (on a dry basis with 15% Ο

2

), for operation with a

load above 70% and with an annual total electrical efficiency above

50%.

NOx levels are measured continuously by the plants’ CEMS and the values logged

are expressed in mg/Nm

3

. On the basis of inventory data, acceptance limits

were not exceeded.